We receive a lot of communications, some of which may stand out. In our cooperative, this month, it is the case of Canadian Plastics editorial about Lego’s retraction. This editorial is also a lesson on research and development for sustainability..

Result of Lego’s tests

Lego must deny its 2019 promise «to use only sustainable materials in its products». Why? Lego had been testing hundreds of materials. For those bricks, recycled plastics have been found to be less durable, less secure, and harder to nest. Their additional production steps also increase pollution.

Conclusion: Lego can’t find a replacement material for its bricks that fits its needs. In September, Lego announced it won’t go with recycled plastics for its bricks.

Eternal pieces?

But we wonder. If Lego can’t find a replacement material, is it because Lego’s bricks are already a durable solution? We ask our coworkers what they did with their Lego. Pieces were given to brother, sister, cousins and neighbors. Some keep it for their children, even for their grandchildren! And we know that it’s not only the case in here.

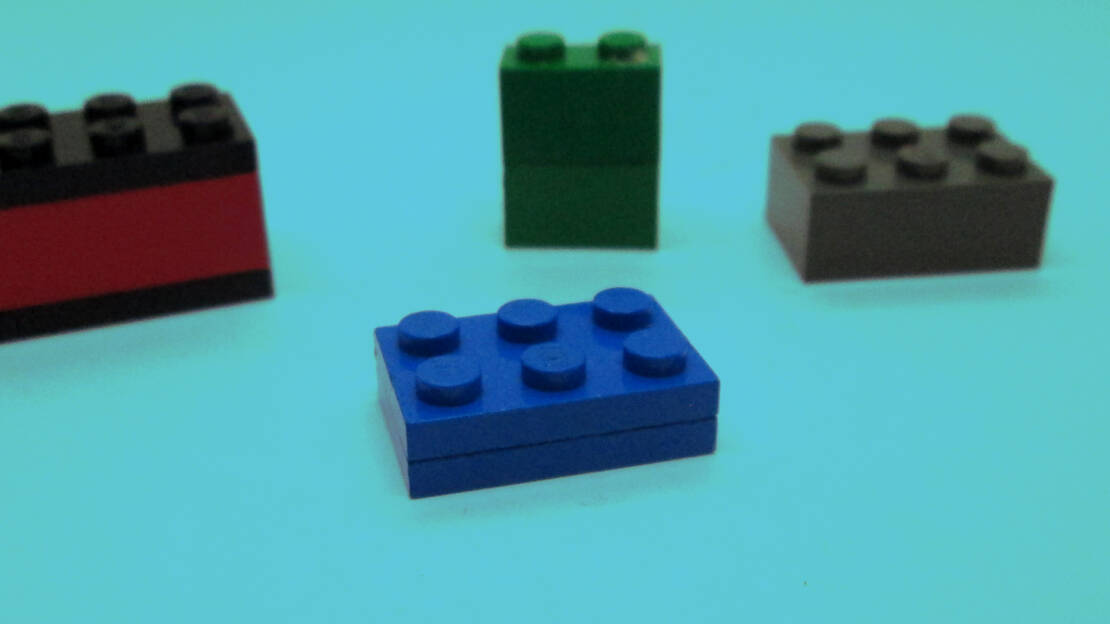

Lego’s bricks aren’t only used to make what is illustrated on the box. Pieces are also reusable to create a lot of magical universes. It was impossible resist creating one while searching pieces for pictures! Isn’t it a great example of how much reuses can be done with plastic pieces?

We believe Lego’s reputation is way over ‘‘clutch power’’ because we think the durability of those pieces also helps to make it famous! One of our employees also said about her Lego giveawayo: «I regret, I should’ve kept them!» Sometimes, keeping a solution, it is how you can be sustainable!

Be warned

Mark Stephen’s editorial is not about always rejecting recycled materials, neither on decisions made because «product development doesn’t work out as hoped.» It is about being sure replacement materials exist before publicizing it.

The editor reminds that Lego did the tests after its public pledge. So, because Lego didn’t verify the feasibility of such a kind of material before proclaiming it, the company must abandon this plan. He uses this example to demonstrate companies must do research first!

Photo by Egor Vikhrev (Unsplash)

We know the limitations

So, are we warned? Yes, we were, and we’ll continue to be! We know it, we face new challenges with recycled materials. Through the process with our clients and partners, we’re transparent about recycled plastics limitations.

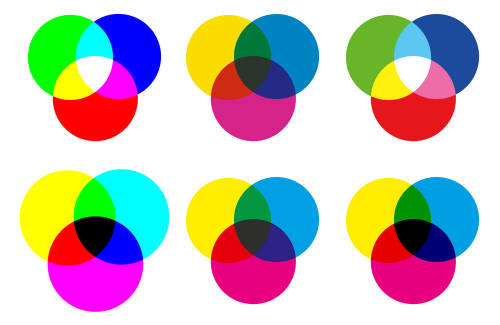

For examples, we can face issues like a less smooth texture, a presence of tiny color dots, a small variation in the piece’s transparency, and, on certain types of recycled plastics, an unsticking of primer.

Recycled plastics aren’t made of pure plastic composition, so it won’t be a perfect plastic. And generally, our imprint will somewhat hide those defects. (You must bring pieces closer to your eyes than your nose to see them!)

We continuously do research and development

We know that we can attenuate those defects by some actions.

Our tests revealed that a reduction of recycled plastics in the composition helps to have a smoother texture. It can be as less as 1%. We can ask our molding partners to play with the pourcentage to deal with this issue. Our molders also place elements in a position to optimize color’s uniformity. Another solution for the tiny dot issues it to suggest black pieces. Why black? That tint color will somewhat absorb unexpected color particles.

It’s almost impossible to have any rejects. That’s why we’re making our positioning tests on them. Rejected pieces are also sent to our partners who use it as recycled plastic when they mold new pieces.

For printers, polypropylene is the most hated plastic! And it’s the most used in recycled plastic pieces. So, we’re doing research and development with collaborators to find the right primer application for this eco-friendly material.

Sustainable solutions

Even if we know the benefits of recycled plastics, we believe it’s useless if it’s used to continuously create new short-termed items. That’s why we also pursue the search for sustainability by focusing on long-termed reusable items.

We also want to put in place sustainable solutions that will continue to improve by itself.